DAF-F

DISSOLVED AIR FLOTATOR

That will run for ages in high density salt and chemical environment

Get a solution within 1 working day

So Flotlife designed DAF series F

That combines the best features

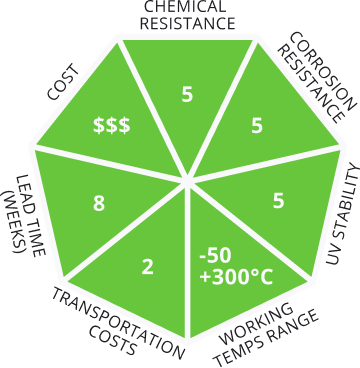

Lightweight as Fiberglass. This feature reduces transporting costs.

Outstanding chemical and corrosion resistance as SS Duplex. It will run for ages without degrading.

2 months production time as PolyPropelene DAF.

UV stable as SS Duplex or SS 316. Can be placed in and outdoors.

Wide working temps like SS Duplex.

Cheapest production than any other. You save at least 30%.

Developed for water treatment facilities with high density of

01

Salts · Acids · Alkalis

Alcohols · Various solvents · Fats

02

03

Oils · Waxes

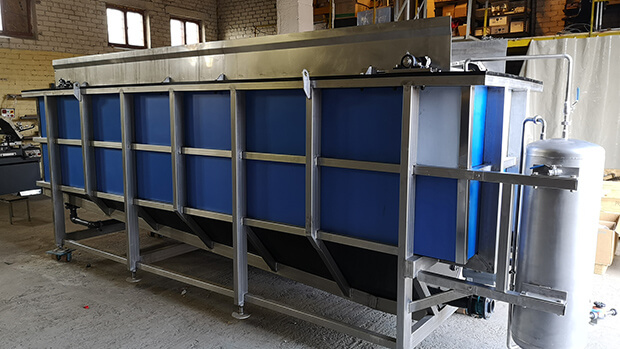

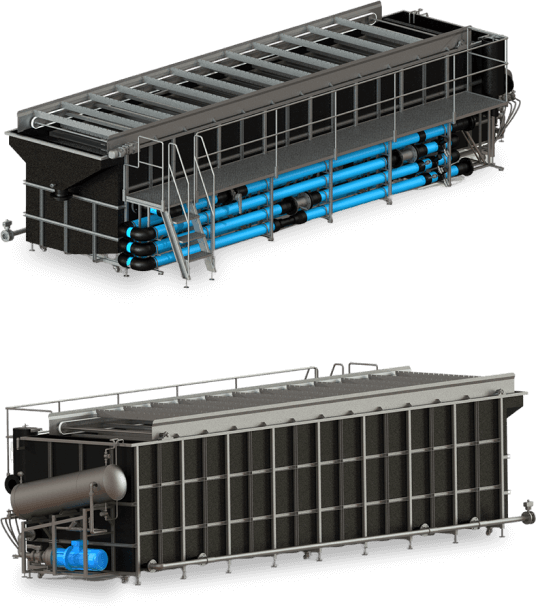

DAF flotation tank

Made from non-metal materials — HD PE (high density polyethylene)

Used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber

High weldability to each other

High tensile trength

High impact strength

Low cost

Solvent resistant. Corrosive and chemical free

Tempeture working range

-50 to +80 °C

UV protected. Can be used

in- and outdoors

Cheap and faster in production than steel tank

vs 1 day

7 days

100 %

guaranteed weld

Density – 940 kg/m³

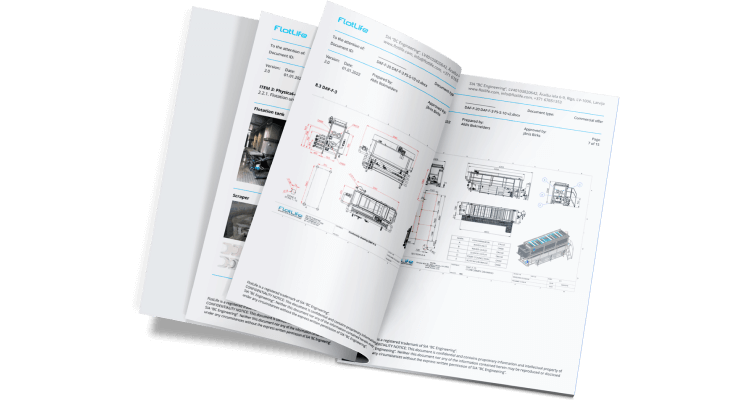

Get a solution within 1 working day

With a quotation you recieve:

Reasonable calculations

Blueprints

Technical data

And you would say

PE? REALLY? PE IS FRAGILE!

TWICE as strong as stainless steel

Corrosive free

Yes. You're right. That's why we've designed special frame to hold the tank

Frame made of Super Duplex compound and totally resistant to corrosion. But it would be economically impractical to use pure Duplex so we've developed a special compound with AISI304 and Duplex. Price is the same as for a classic steel tank.

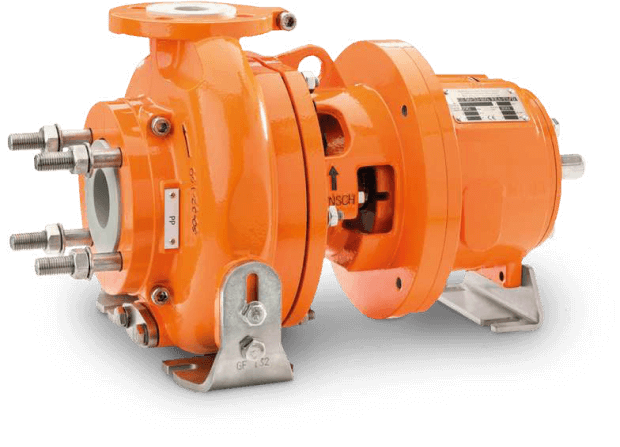

Pumps made from industrial plastic save up to 2'000 € per 2 years

Compared to classic centrifugal pump:

-20%

lower cost. Impeller is 3D-printed. It's much easier to produce it

-20%

less energy consumption with the same power

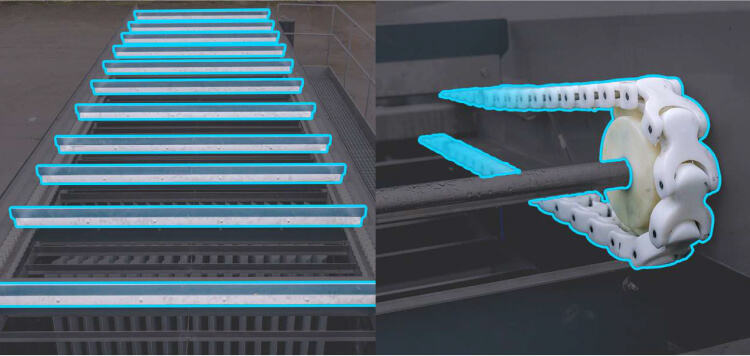

Steel impeller after 1 year of use in high chloride environment

Flotlife impeller running for 3 years in the same conditions

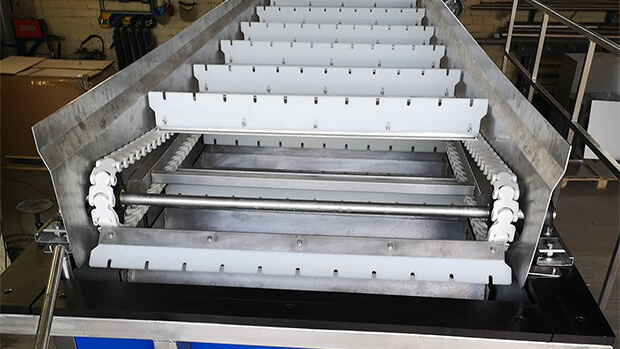

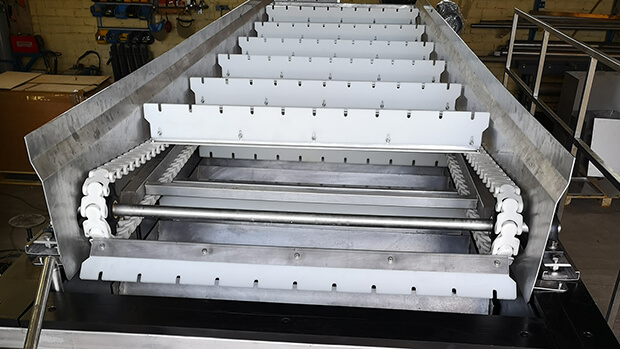

Scrappers made from industrial plastic

Corrosive and chemical free

10 times lighter than metal

80% power saving

As quite as a man whisper

DAF-F efficiency

Made from non-metal materials — HD PE (high density polyethylene)

20% less sludge volume with sludge dewatering grid and skimming process

Sludge dewatering grid

01

Framework of angled, steel plates provides small pockets of surface area that locks float sludge in its place as it reaches the water's surface

02

When the sludge has become thick enough to build up above the grid plates, the skimmer blades begin pushing them toward the sludge ramp for removal

03

This float material self-dewaters before leaving the DAF tank. It results 20% drier sludge up to 20% reduced volume for disposal

Sludge Skimming Process

Wastewater enters the tank on the left side and exits out the right. As a layer of sludge begins to form at the water's surface, the skimmer blades are going to push the sludge in а counter-current skimmer folds the sludge in the opposite direction, from right to left

Need a specific wastewater flow? Or limited in space?

We design any custom solutions

Real world cases

350'000 Euros saved by fish productions in Vietnam

5 facilities located close to the ocean shore were equipped with stainless steel DAF units. Salty water and high salty moistore inside the facility totally degraded steel DAF within 3 years.

That could led to a repeat purchase of DAF for each facility and 70'000 Euros loss per each every 3 years.

DAF-F with PEHD tank completely solved the problem.

2021

50 m³/h

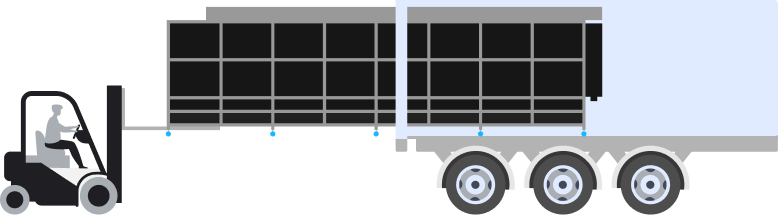

SAVE up to 50% in-situ construction

DAF delivered pre-assembled in containers

Large models divided in 2 parts easy to connect

Requires 30% less concrete base

DAF equipped with supports that distribute the weight.

Easy to adjust the alignment

Place in place with just two men

Wheels on bottom of the DAF make unloading process fast and doesn't require any special equipment like loader.

And doesn't require any equipment to place DAF on it's place.

What's included

Full project design will all the calculation

3D model

Manual with detailed

assembly process

Packaging and shipping preparation

Save 18'000 € per year

with connected DAF

—

This is Rowan. (That's a real case but we couldn't place Rowan's photo). He maintained (now he is fired) wastewater treatment facility 8 hours per day 7 days per week.

—

Operation laboring cost for Rowan is approx. 1'500 € per month. That's 18'000 € per year.

—

And Rowan is human. He noticed that coagulant has not been dosed for at least 1 week. The water hasn't been treated.

—

That mistake cost our partner 10'000 € fine.

+

This is a connected DAF. The remote control system maintains same the Rowan did. 24 hours 7 days per week.

+

Operating laboring cost 200 € per month. Or 2'400 € per year.

+

Connected DAF is an AI, algorithm. It reads data from the all the sensors integrated in the whole treatment facility. DAF will alert if something is out of normal status.

+

It excludes the human factor and ensures that it will run like a Swiss watch.

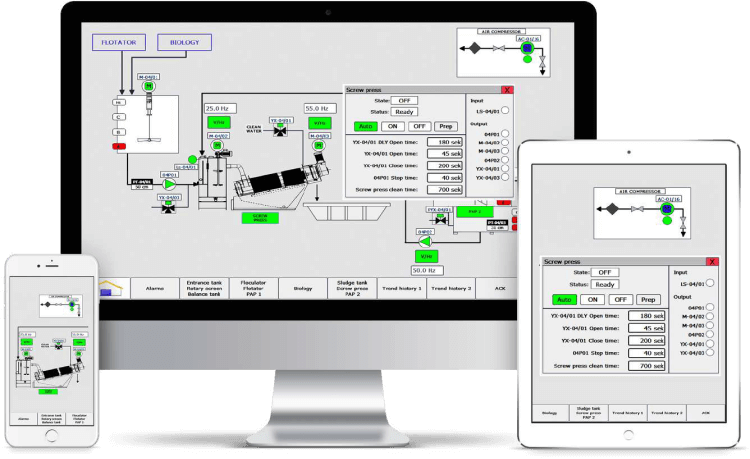

Integrate the whole treatment facility to DAF

with remote control and monitoring system

01

Flotation status and alerts real-time dashboard

02

Availiable on desktop or mobile devices

03

Control and stabilize flotation process before it gets out of control

04

Access to historical data offers enhanced insight for better decision making

05

Replacement of maintenance workforce by a smart system reduces WWT operational costs

15+

years of experience

70+

projects launched

30+

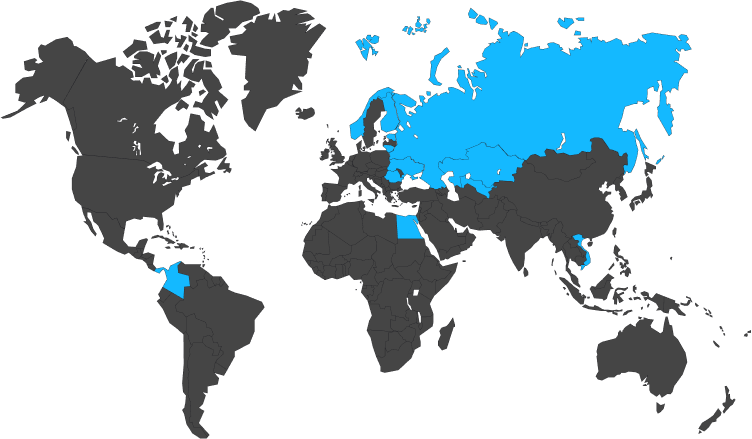

countries use our products

Production based in Latvia

Shipping worldwide by land and sea

All-in-All.

Shall we start?

Contact us with your treatment challenges:

Product and technology are the main priority we should invest. Yanis Birks, CEO